By 2032, nearly 25 percent of the U.S. workforce is projected to be 55 and older, according to the U.S. Bureau of Labor Statistics (BLS).

And surveys show that more and more Americans are working past the traditional retirement age of 65.

What does it mean for your company? How can you prevent injuries as your workforce ages?

Why older workers are at higher risk for serious injury

Although older workers are injured less frequently than younger workers, their injuries are typically more severe and take longer to recover from.

They may have comorbidities, such as diabetes or heart disease, that lead to slower recovery and higher medical costs — older workers typically take twice the recuperation time of younger employees, according to the BLS .

There are physiological reasons why aging employees are at higher risk for serious injury.

The first is muscle strength. The aging process leads to distinct muscle mass and strength loss, according to the National Library of Medicine . In fact, muscle strength declines from people older than 40 between16.6% and 40.9%.

The second is hearing and vision loss. As people age, the chances of experiencing hearing and vision loss increase. These changes can make employees less aware of their surroundings, and therefore more susceptible to injury. For example, a construction worker who can’t hear the warning beep of a vehicle backing up.

But the No. 1 risk for older workers is falls, and they can result in more serious injuries than you might expect. For example, workers who’ve slipped and fallen on ice while shoveling have ended up with multiple fractures or even traumatic brain injuries.

Four tips for preventing injuries among older workers

Workplace safety is important for all your workers, no matter their age or experience level. A comprehensive safety program will benefit your entire workforce.

Here are a few practical ideas to better protect your older workers in particular.

1. Enhance injury prevention through a wellness program

Employers can help prevent strains, sprains and falls by encouraging improved flexibility, strength and balance.

Consider starting a flex and stretch program, walking program or covering all or a part of the cost of gym memberships — especially if there’s one nearby with a pool. Swimming is a great form of exercise for injury prevention because it improves strength and flexibility without high impact.

Some companies are constructing workout centers onsite for employee use or holding exercise classes such as yoga, Pilates or Tai Chi.

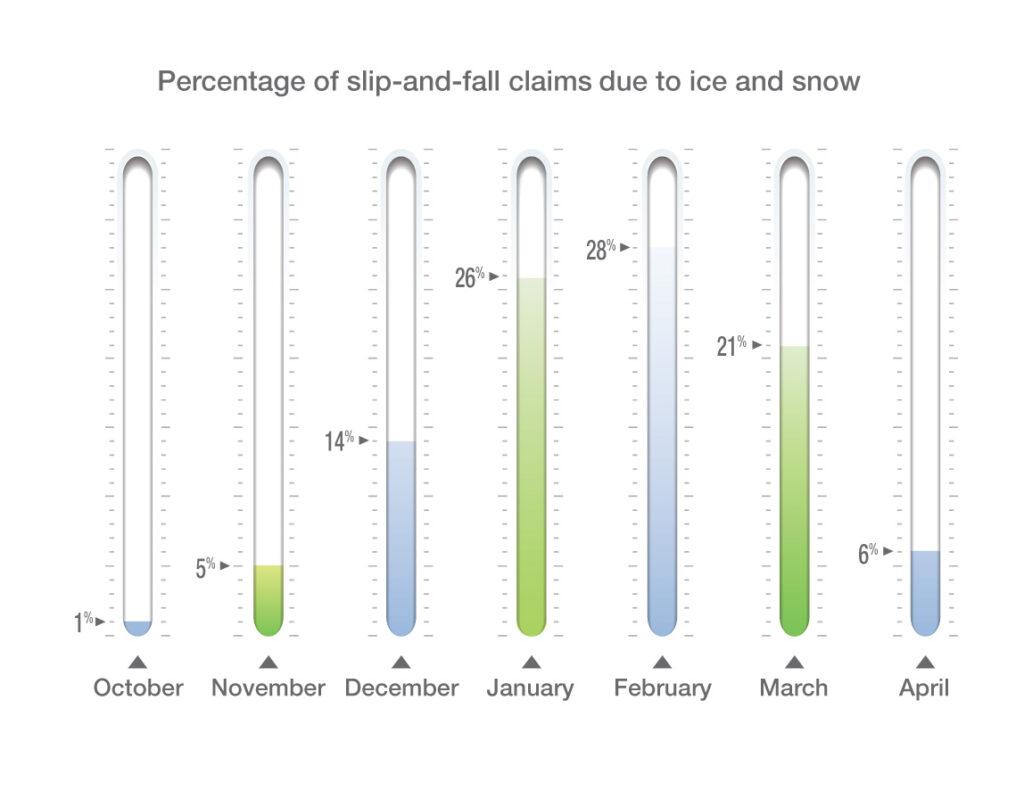

2. Prevent slip-and-fall injuries

Ensure a safe working environment by maintaining parking lots and sidewalks, keeping walkways dry and clear of clutter and applying slip-resistant floor treatments in appropriate areas. Then, make sure your employees are aware of the risks of slip-and-fall injuries.

Oftentimes, simple steps like wearing appropriate footwear, walking cautiously in wet or slippery conditions and using handrails can prevent a fall.

For employees who spend any time working outside during the winter — like bus drivers, maintenance workers or playground supervisors — encourage wearing traction footwear. Employees who work in environments that are sometimes wet or greasy, such as kitchens or hospitals, should wear slip-resistant footwear. (See a list of slip-and-fall prevention vendors recommended by SFM.)

3. Make sure employees can meet the physical requirements of the job

For new hires, require a pre-employment physical to ensure they are capable of all the tasks the job requires. Make sure the person doing the testing has an up-to-date job description that includes all the essential functions. As part of the examination, have the physician review a medical history questionnaire, which may reveal issues not apparent during the physical exam. The cost of testing will likely pay for itself if you prevent even one back or shoulder injury.

State laws and the federal Americans with Disabilities Act govern how pre-employment physicals can be conducted and used, so it’s important to consult your legal counsel before starting such a program at your company. Any tests used must be job-related and consistent with business necessity. Generally, if applicants have disabilities that interfere with their ability to participate in the testing process, result in them failing the exam, or both, employers must engage in an interactive reasonable accommodation process.

For more information see the Pre-employment physical examinations Legal Advisory.

4. Improve ergonomics

Focusing on ergonomics becomes even more important with older workers. Perform ergonomic evaluations in your employees’ work areas — whether they work at a desk, in a vehicle, on a production floor or in another environment. Ask your employees for their suggestions on how their jobs could be altered to avoid fatigue or soreness.

Eliminate manual lifting wherever possible by changing the layout of the work area or providing lifting equipment. If lifting is required, use proper lifting technique. This is especially important in health care, where injuries from patient handling are common.

For repetitive tasks, practice job rotation. This requires cross-training employees on more than one job, which can be a benefit if someone quits or is absent.

Older workers offer knowledge, experience and expertise that many employers find desirable and will try to retain in the coming years. A little planning and attention can help keep your workforce safe and productive at any age.

Originally published in November 2018; updated in August 2024 and November 2025.