Throughout the colder months of the year, you must continuously be wary of the dangers of slipping on the snow and ice.

And this is especially true at the tail end of winter. Warmer weather may lull you into a false sense of security, but thawing and refreezing can make roads and walkways even more treacherous.

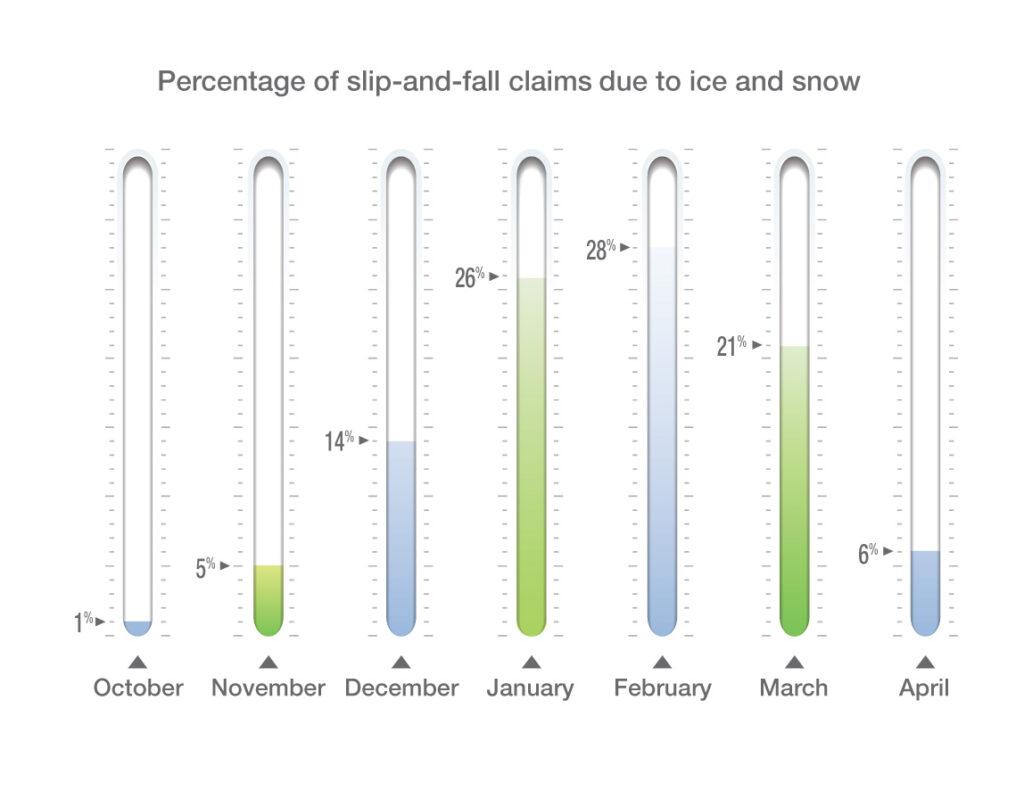

Each year, hundreds of employees insured by SFM report falling because of snow and ice — it’s one of the most common causes of injuries.

Employers reported 479,480 nonfatal injuries involving falls, slips, or trips in 2023-2024, according to the U.S. Bureau of Labor Statistics (BLS) , and there were 885 fatal workplace falls, slips, and trips in 2023 across all industries – one of the highest‑impact categories of workplace fatalities .

According to SFM claims data, 25 percent of ice- and snow-related falls occur in parking lots and 20 percent of slips and falls that occur in parking lots result in lost time from work.

Meanwhile, SFM estimates the average winter slip-and-fall lost-time claim costs range from $50,000 to $55,000. The costs — direct and indirect — mount quickly and can’t be ignored.

Staying safe from slips and falls

Incidents can be serious. According to the most recent data from the BLS, work-related fatalities due to falls, slips, and trips resulted in:

- 805 fatalities in 2020

- 850 fatalities in 2021

- 865 fatalities in 2022

- 885 fatalities in 2023

About 20 percent of all workplace deaths are attributed to slips, trips and falls, per OSHA.

Employers must ensure walking surfaces at the workplace are free of snow and ice, according to OSHA safety standards.

To mitigate the perils of getting around during winter, there are many preventive measures employers can implement to decrease the chance of on-the-job injuries.

- Make sure gutters and downspouts flow away from walkways to avoid the dangerous freeze-thaw-refreeze cycle

- Redirect any water flowing on walkways to avoid puddles

- Treat walkways at high-hazard times and warn employees about potential hazards

- Manage snow piles near walkways to avoid melting snow refreezing to ice

- Plow snow below the grade of walkways to minimize downward flow

- Repair walkways to eliminate uneven surfaces that collect water and ice

- Designate safe paths of travel to and from building to discourage potentially dangerous shortcuts

Remind employees about winter hazards using SFM resources

With a few simple precautions, falls on snow and ice resulting in costly injuries can be easily avoided. Employee awareness is key.

“It’s important to keep reminding employees of the risks of winter slips and falls, and how to avoid them, throughout the season,” Wendel said. “We’ve tried to make that easy for employers by offering a variety of different resources.”

Consider some tips from SFM:

- Do the penguin shuffle: Focus on your footing, walk flat-footed, take short steps to keep your center of balance over your feet

- Take it slow: Walk slowly on snow and ice to avoid a slip

- Wear proper footwear for the weather: Choose footwear with non-slip soles, deep treads and wide, low heels; add cleats or traction footwear for extra grip

- Carry only what you can: Carrying less or using a bag or backpack decreases your chance of falling — and keeps your hands free if you do

- Watch for changing conditions: Monitor the weather; cycles of freezing, melting and re-freezing are especially dangerous

- Don’t be distracted: Put your cellphone away while walking and focus on where you’re going

- Step down, not out, from curbs and cars: Falls in parking lots are common — step flat-footed off curbs, step down with both feet when exiting your vehicle

- Walk on marked paths and avoid short cuts: Short cuts are likely to be icy and put you in danger of slipping, and backdoors, alleys garbage/refuse areas can be especially treacherous

- Report icy conditions: Tell a supervisor or maintenance person if you spot slippery areas so they can shovel or salt problem areas

- Spread salt on ice: If you spot a slippery area and salt is available, spread it yourself

These tips and being aware of winter conditions can go a long way toward ensuring a winter spent upright and safe.

“Winter in the Upper Midwest often extends into early spring,” Wendel said. “By taking the necessary precautions and staying vigilant, workers can remain safe.”

Originally posted January 2018; updated February 2026.