Prevent strains and sprains through proper ergonomics

Strains and sprains are some of the most common injuries reported to SFM. Strains are soft tissue injuries that can affect muscles, nerves, tendons, joints and cartilage in the limbs, neck and lower back. Sprains are injuries to the bands of tissues — ligaments — that connect bones together.

Strain and sprain injuries are often caused by completing tasks that were set up without ergonomics in mind. Ergonomics is the study of the relationship between people and their activities, equipment and environment. Tasks might be too heavy, awkward or repetitive for employees to safely compete, which increases their chances of developing musculoskeletal disorders (MSDs).

As an employer, it’s important to ensure your employees maintain their comfort and safety while completing tasks to reduce their risk of developing strain or sprain injuries.

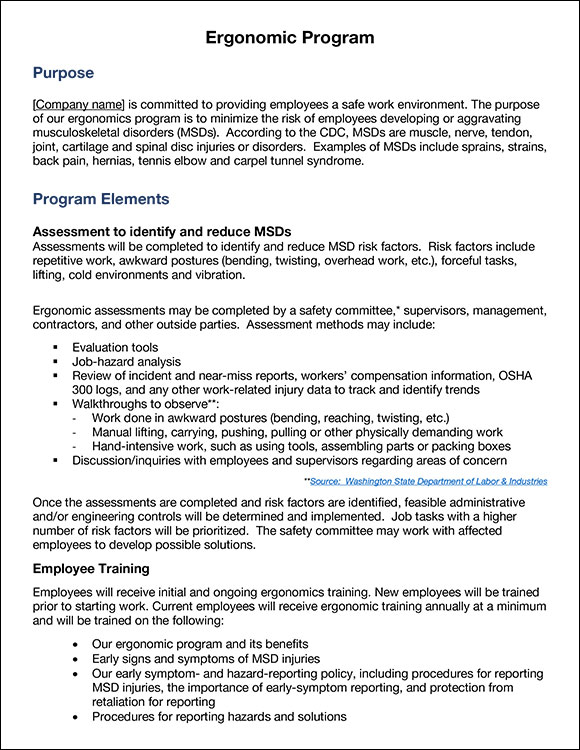

To develop an ergonomic program for your organization, download our ergonomic program sample.

Best practices for reducing strains

To optimize ergonomics and reduce strains and sprains in the workplace follow these best practices:

- Determine the causes of strains and sprains at your organization

- Evaluate employees’ job tasks and identify those with potential risk factors

- Reduce hazards in employees’ job tasks

Identify potential hazards and risk factors

The most important first step in preventing strains and sprains is identifying potential ergonomic risk factors.

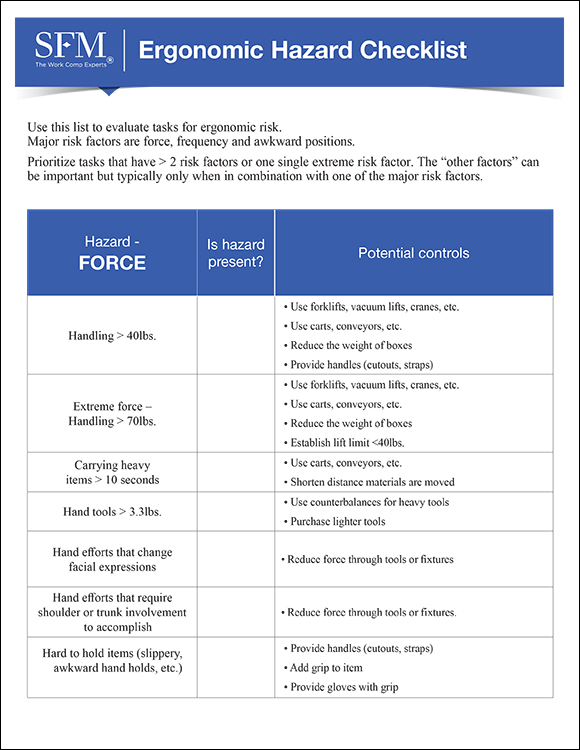

Force (intensity of exertion), frequency (how long and often a task is completed) and awkward position (not maintaining a neutral position) are the three main ergonomic hazards. Risks elevate when these hazards are combined.

As an employer, you can identify risk factors by:

- Conducting walkthroughs of your facility that focus on identifying risk factors

- Using checklists to help identify risk factors

- Assessing your organization’s past injury data to identify where prior strain and sprain injuries occurred

- Polling your workers to identify tasks that cause discomfort or pain

Hierarchy of safety and ergonomic solutions

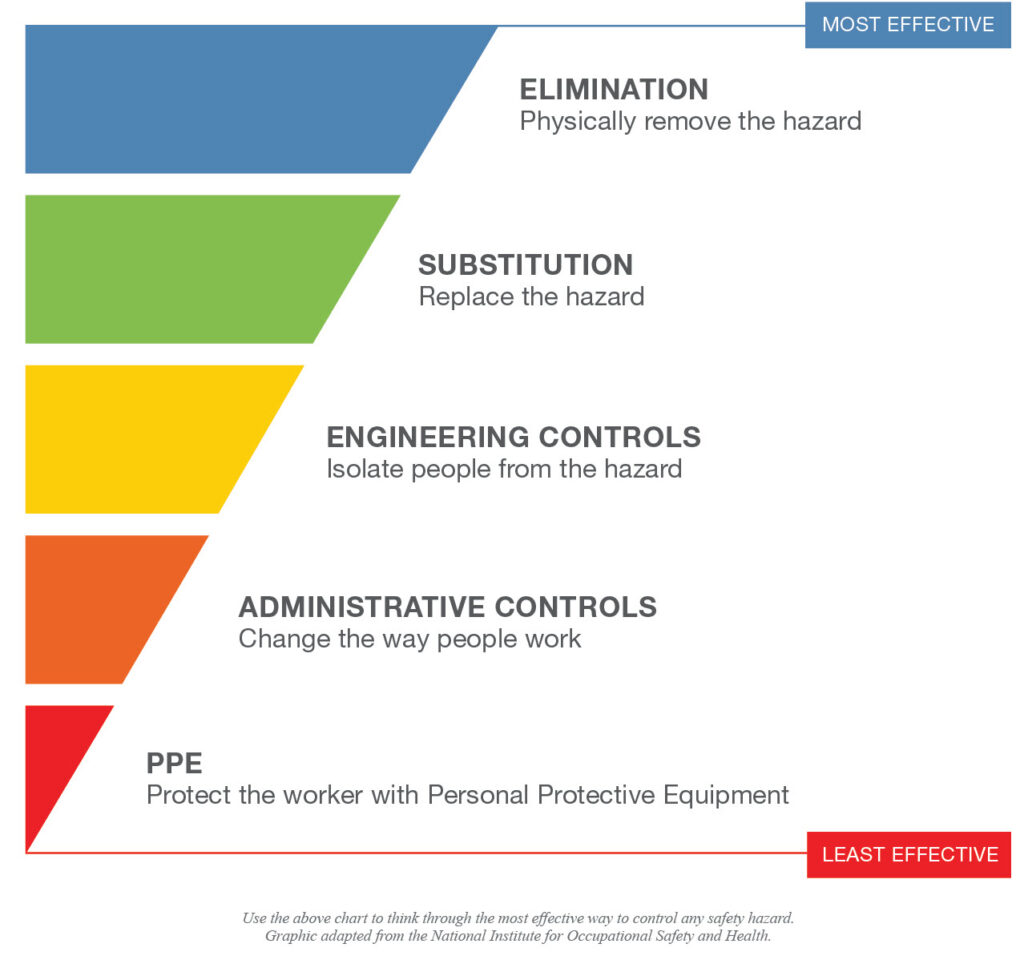

Now that you’ve identified strain and sprain risk factors within your organization, it’s time to determine ergonomic and safety solutions (controls) to address these hazards. Keep in mind that not all safety solutions are created equal and some are more effective than others.

Categories of actions/safety controls have been rated by effectiveness by the National Institute for Occupational Safety and Health (NIOSH) as shown in the diagram below. Safety controls at the top of the pyramid are most effective, so focus on these when implementing solutions to reduce strain and sprain injuries.

For example, it’s much more effective to physically remove or replace a hazard, than it is to change the way people work or have employees wear personal protective equipment (PPE).

Eliminate: Physically remove the hazard

Identify tasks where equipment can be used instead of an employee.

Substitute: Replace the hazard

Change the element of the task that makes it challenging, such as the size or weight of something being lifted.

Engineering controls: Isolate people from the hazard

Update tasks and procedures to reduce risks, focusing on high force movements, repetitive tasks and awkward positions.

Administrative controls: Change the way people work

Create safety procedures such as implementing a safe lifting limit, rotating jobs between workers, and implementing daily stretching and movement.

Personal Protective Equipment: Protect workers with PPE

Provide workers with protective gear such as gloves, helmets, protective eyewear and other safety gear.

Strain and sprain safety solutions by risk type

To guide you in finding safety and ergonomic solutions your organization can implement to prevent or reduce strain and sprain injuries, check out these examples listed below for each risk type. Solutions for each category are listed in order from most to least effective following the hierarchy shown above.

Force risks

Examples of risks:

1. Handling and lifting loads, especially when bending and twisting

2. Repetitive or high force tasks

3. Awkward and static postures or prolonged sitting and standing

Possible solutions/controls:

| Elimination | Avoid unnecessary material handling; combine operations or reduce distance items are moved | |

| Elimination | Avoid lifting by using mechanical equipment like forklifts, vacuum lifts, cranes, etc. | |

| Elimination | Use carts, conveyors and other equipment to avoid carrying and reduce push/pull forces | |

| Substitution | Reduce the size of bins or boxes to reduce the weight handled | |

| Engineering controls | Provide handles when possible (cutouts, straps) for easy grip of containers | |

| Engineering controls | Use counterbalance for heavy tools | |

| Administrative controls | Limit the number of items handled or lifted at one time |

Awkward position risks

Examples of risks:

1. Twisting

2. Bending at the waist

3. Lifting or lowering items above shoulder height or below the knees

Possible solutions/controls:

| Elimination | Practice good housekeeping and remove clutter to eliminate reaching | |

| Elimination | Store materials between mid-thigh and chest height | |

| Engineering controls | Provide adjustable chairs and workstations | |

| Engineering controls | Use equipment such as lift tables and adjustable pallet jacks to raise product and work off the floor | |

| Engineering controls | Rearrange work areas to keep frequently used materials and tools in front of and close to employee | |

| Engineering controls | Use lifts with turntable or roller tops to reduce reaching | |

| Engineering controls | Angle boxes and containers at a 45-degree angle to allow for easier access (while loading and unloading items in boxes) | |

| Engineering controls | Redesign work area to encourage employees to pivot their feet and step rather than twist |

Frequency risks

Examples of risks:

1. Continuous use of specific body part during entire shift

2. Highly repetitive work tasks (15 or more times per minute)

3. Rushing to complete tasks

Possible solutions/controls:

| Elimination | Automate processes through machines or robots | |

| Administrative controls | Rotate employees to less repetitive jobs; every two to four hours is best | |

| Administrative controls | Expand the job to include a greater variety of tasks (job expansion) | |

| Administrative controls | Split work among two or more employees | |

| Administrative controls | Allow for rest periods |

Other risk factors

Examples of risks:

1. Environmental (heat or cold)

2. Vibration

3. Contact stress

Possible solutions/controls:

| Substitution | Purchase equipment with less vibration | |

| Engineering controls | Consider anti-vibration gloves (if applicable) | |

| Engineering controls | Place padding on work surface edges to reduce contact stress | |

| Engineering controls | If the job requires standing, provide anti-fatigue mats and a footrest or rail to raise one leg | |

| Engineering controls | Select hand tools appropriate for the job as outlined by the CDC |

SFM resources

Additional resources

NIOSH job hazard identification checklists: